How to Make a Foam Sanding Block Work Again

7 Pro-Approved Tips for How to Sand Woodwork by Hand

Special tools and high-quality sandpaper produce corking results with less effort

![]() Time

Time

A full twenty-four hours

![]() Complexity

Complexity

Beginner

![]() Toll

Toll

Less than $20

Introduction

With a few special tools and expert sandpaper, you tin shine wood easily and rapidly with first-class results. Ofttimes even improve than with a power sander. We tell you lot how to choose the best sandpaper for wood and demonstrate several of our favorite tools.

Tools Required

Materials Required

- Rigid foam insulation

- Sandpaper

- Spray adhesive

Video: How to Sand Forest Past Hand

I know, you lot're probably thinking, "Yuck, I hate sanding. " But the truth is that with top-quality sandpaper and a few special tools, sanding past hand can be made a lot more pleasant. Sure, hand sanding is a footling slower than power sanding. But information technology's quieter and doesn't spew dust all over the place. And besides, in that location are some places that you can't reach with power sanders. In this article, we'll tell you how to cull the best type of sandpaper for the job and show you some of our favorite hand-sanding tools.

Project pace-by-step (9)

Pace 1

Tip 1: Cull Three Grits to Observe the Best Sandpaper for Wood

When you sand, you're scraping away material from the surface to remove imperfections or to shape and contour edges. The goal is to start with the sandpaper that's just coarse enough to remove the worst defects easily. Starting with sandpaper that's as well coarse will mean extra sanding later on with effectively-dust papers to remove the deep scratches left by the fibroid dust. On the other manus, if y'all start with sandpaper that's too fine, information technology'll take forever to sand out defects. In most cases, 80-dust paper is a practiced starting signal for sanding planed or shaped woods. Get-go with 100-grit if the wood is already smooth with no deep scratches, planer marks or other surface defects.

Both 80- and 100-grit leave a network of fine scratches behind, so the next footstep is to sand with a fiddling effectively dust. This replaces the scratches with smaller, less visible ones. If you started with fourscore-grit paper, skip to 120-grit newspaper, or if 100 then to 150. Finally, sand with 220-grit sandpaper. For nigh types of wood, this is the finest dust you'll need. Wood with a very dense grain, like ebony, may require one additional sanding step with 320- or 400-grit paper to eliminate visible scratches. Hither are the two grit progressions nosotros recommend: lxxx/120/220 and 100/150/220.

Step 2

Tip two: Use a Sanding Block for Flat Surfaces

It'due south tempting to just fold a slice of sandpaper and go to work. Simply you'll get better results with far less effort if you employ a sanding block. The block distributes sanding pressure more evenly and maintains a flatter surface. A block also lets y'all bear downwards harder. You can make a sanding block by cutting a small square of rigid foam or gluing a thin layer of cork to a wood block. Or you tin can buy a simple rubber sanding block at almost any hardware store, paint shop or home centre. But for the ultimate in hand-sanding convenience and efficiency, consider ordering a sanding block similar the one we show hither. Its shape conforms comfortably to your paw, and the well-designed clamps make it piece of cake to install quarter sheets of sandpaper.

Buy information technology on Amazon.

The biggest error I see people brand when they're using a sanding block is failing to change paper often enough. To encourage more frequent irresolute, use a straightedge and utility knife to cut to size a bunch of newspaper sheets in each of the grits you'll be using. With exact-size sheets on hand, information technology'll be easy to modify the newspaper oft—as soon every bit you notice it isn't cutting efficiently.

In full general, information technology'south best to sand with the grain of the woods, especially for the final grits. But to remove deep scratches and stains, it's OK to angle beyond the grain, upwards to about 45 degrees for the initial sanding. This goes contrary to popular stance, only it's a good method to remove material speedily. But before switching to the next finer grit, sand with the grain to remove all cross-grain scratches.

Step 3

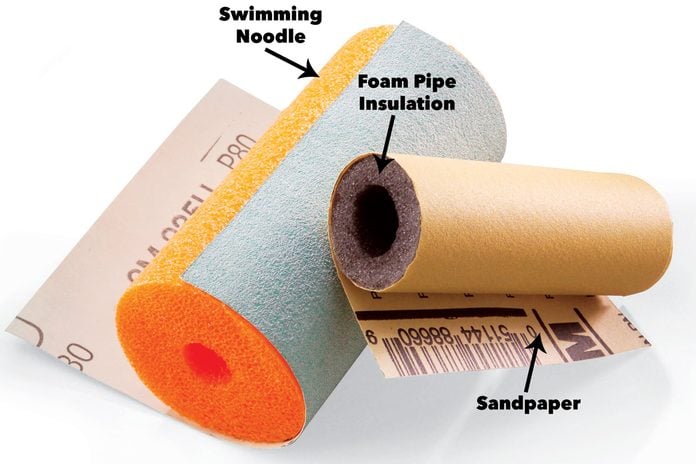

Tip 3: Foam Pipe Insulation and Swimming Noodles Make Swell Sanding Pads

Soft, flexible cream makes a corking base for sandpaper because you can hands clasp or shrink it to fit a diversity of shapes. Wrap sandpaper around scraps of foam pipage insulation to sand medium-size coves. For large concave surfaces, apply scraps of foam swimming noodles. These are easy to cut with a bread pocketknife. Stick paper to the inside surface of pipe insulation to make a sanding pad for dowels and other cylindrical shapes. You can adapt many household objects to become sanding pads if you similar the contours and they're a bit soft.

Cheque out these tips for using your noodles at domicile, in the garage, around the chiliad and at the pool!

Pace 4

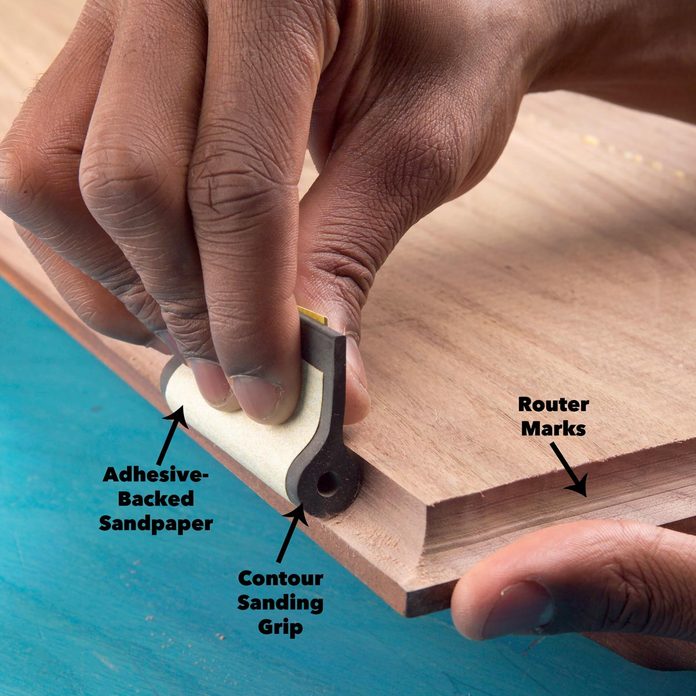

Tip 4: Salvage Your Fingers—Try Contour Sanding Grips

Profile sanding grips make it easier to sand molding profiles because you can get a proficient grip and the shape stays consistent every bit y'all sand. We're sanding a coved edge created with a router. You can buy a ready of these shaped prophylactic sanding pads. (They're as well sold under the Tadpole make name.) Simply choose the one that fits the contour y'all're sanding and wrap sandpaper around it. I similar to use sandpaper with pressure-sensitive agglutinative on the back and stick it correct to the pad. You lot can purchase minor rolls of adhesive-backed sandpaper at home centers and woodworking supply stores.

Buy them on Amazon.

Stride v

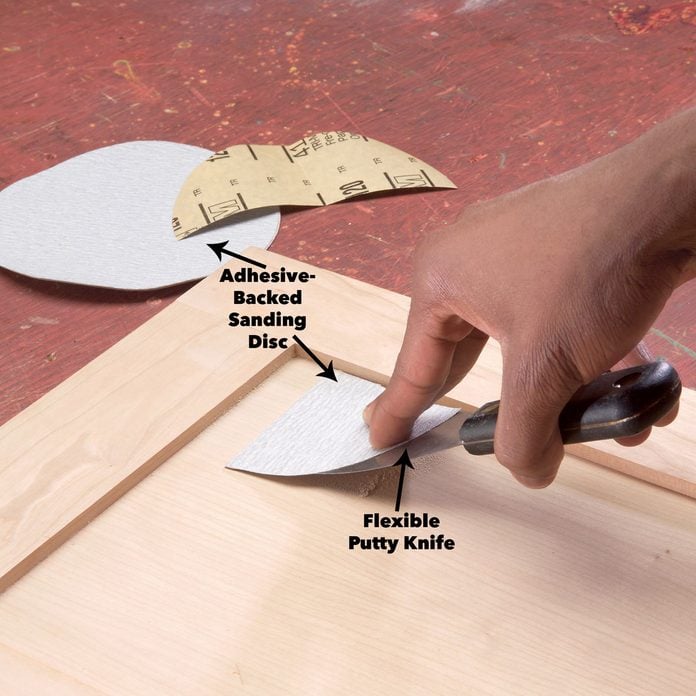

Tip 5: Stick Sandpaper to a Putty Knife to Reach into Tight Corners

It's difficult to sand "with the grain" into tight corners without scratching the adjacent woods. Here'southward a tip that works great for those difficult-to-accomplish areas. Wrap an adhesive-backed sanding find the border of a flexible putty knife. Trim the sandpaper affluent to the border of the putty pocketknife with a utility knife. Adhesive-backed sandpaper discs are readily available at home centers and hardware stores. Otherwise, y'all can use spray agglutinative to mount regular sandpaper or buy a gyre of sandpaper with agglutinative backing.

Footstep vi

Tip 6: Buy 'Clog-Resistant' Sandpaper for Sanding Painted Surfaces

Paint and resinous wood similar pine volition clog most types of sandpaper quickly. To avoid using reams of sandpaper, look for sandpaper labeled every bit "no-clog" or "clog-resistant." It's coated with a soapy film, called stearate, that is shed as you sand, taking the pigment or resin with it and leaving the grit exposed for more efficient sanding. This "no-load" newspaper is easy to recognize. Expect for a mottled grayness or colored surface. Two mutual types of sandpaper, brown aluminum oxide and yellow garnet, are non coated and will clog easily. Clog-resistant sandpaper costs a footling more, just it'due south worth information technology because information technology'll last three or iv times longer and relieve yous sanding fourth dimension.

Buy it on Amazon.

Step 7

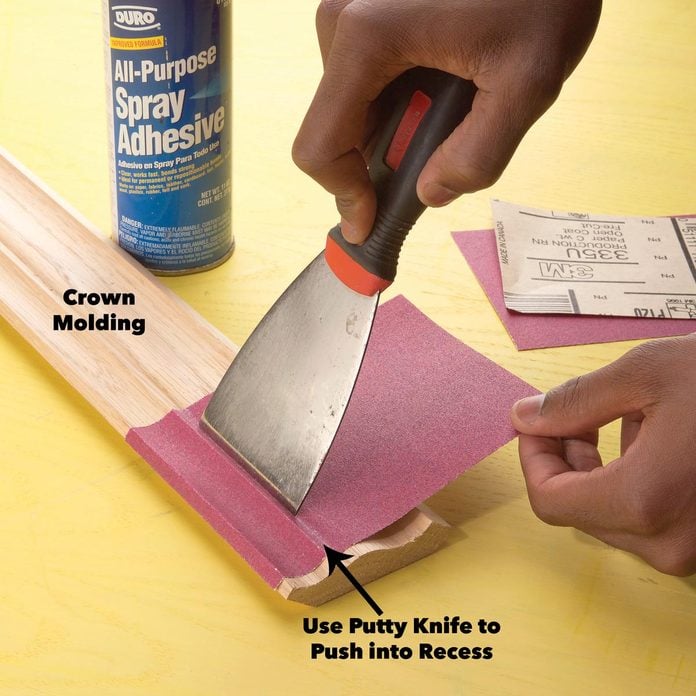

Tip seven: Brand a Custom Sanding Cake to Speed Upward Sanding of Complex Shapes

Scraps of rigid cream insulation (extruded polystyrene) make great sanding blocks and have the reward of existence piece of cake to shape. And y'all'll be able to make a sanding block that conforms to your molding profile. Make three blocks while you're at it. Then glue three progressively finer dust papers to the blocks to complete your sanding sequence. If you lot don't take any extruded polystyrene, ask for scraps at a local edifice site or look for a damaged sheet at a abode centre or lumberyard.

To begin, spray the molding and the backside of 120-grit sandpaper with spray adhesive. Stick it to the molding, making sure to printing it into recesses with the blade of a putty pocketknife.

Stride viii

Sand a Foam Cake to the Contour

Rub a block of rigid foam insulation over the sandpaper until it conforms to the molding's contour.

Stride ix

Attach Sandpaper to the Block

Coat the cream block and the dorsum of the sandpaper with spray adhesive. Carefully stick the sandpaper to the block and sand the molding.

This contour sander has 1 drawback. It'due south hard to fit the sandpaper tightly into the sharp corners of the custom-shaped block. This can outcome in rounded-over edges on some molding profiles. To forestall this, slice the sandpaper with a utility knife in the "creases" and press information technology tight to the block with a putty knife. The other solution is to cut the custom-shaped block into sections to eliminate the parts that could round over a abrupt profile. Sand these areas separately with a small square sanding cake or a small piece of folded paper.

Salvage yourself some time and hassle during your side by side woodworking project with 1 (or 41!) of these genius sanding tips.

Every production is independently selected by our editors. If you purchase something through our links, nosotros may earn an affiliate committee.

Originally Published: Baronial 26, 2019

Source: https://www.familyhandyman.com/project/how-to-sand-woodwork-by-hand/

0 Response to "How to Make a Foam Sanding Block Work Again"

Postar um comentário